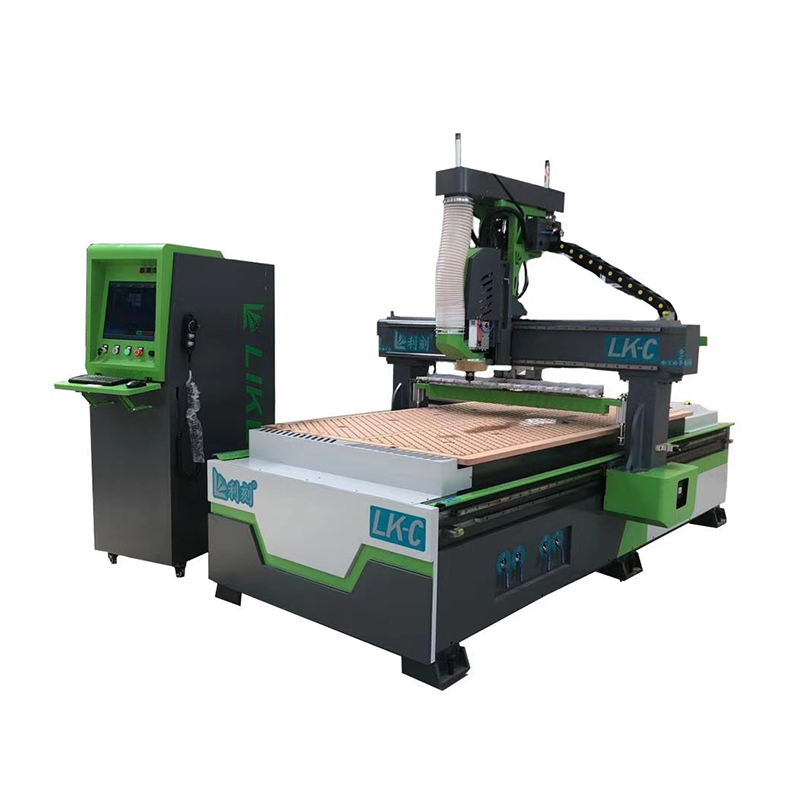

LKC Straight Atc 12 Gravur a Schneiden Holzbearbeitung Cnc Router

| LKC | Equipéiert | notéiert | |||

| Aarbechtsschlag (X*Y*Z) | 1220 * 2440 * 300 mm | ● | |||

| Spindel | Mark | HQD | ● | ||

| kw | CS9KW(ISO30) | ● | |||

| Ofkillung | Loft cool | ● | |||

| Vitesse | 6000-24000 U/min | ● | |||

| Fuert System | Fuert | Servo fueren | ● | ||

| Fuert Motor | TAIWAN DELTA 1000W | ● | |||

| Servo | TAIWAN DELTA | ● | |||

| Inverter | Mark | FULLING | ● | ||

| KW | 11KW justierbar | ● | |||

| Kontroll System | SYNTEC | ● | |||

| Zeechnen Software | ALphacam 2014 | ● | |||

| Eisebunn | HIWIH (25#) | ● | |||

| Schrauwen | TBI32-10 | ● | |||

| Aarbecht Plack | Vakuum Dësch | ● | 4 opgedeelt Beräich | ||

| Schmieren | Automatesch | ● | |||

| Foussschalter | 1 stk | ● | |||

| Positioun Zylinder | 2 fir X, 3 fir Y | ● | |||

| Luede Assistent | Ausluede Apparat | ● | |||

| Reduzéierer | Japan SHIMPO | ● | |||

| Rack | Taiwan Helical Rack (M2) | ● | |||

| Vakuum Pompel | Mark | LIKE spezialiséiert | ○ | ||

| KW | 9 kWt | ○ | |||

| Ofkillung | Waasser cool | ○ | |||

| kabel | Shanghai ECHU (CE Standard) | ● | |||

| Elektronesch Kontroll | CE Norm | ● | |||

| Kierper Struktur | Verstäerkt mat Sträif StahlAn milling no Alterung | ● | |||

| Standby Vitesse | X Achs | 80 m/min | ● | ||

| Y-Achs | 80 m/min | ● | |||

| Z Achs | 15 m/min | ● | |||

| Max Aarbecht Vitesse | X Achs | 25 m/min | ● | Verschidde fir Material a Konscht | |

| Y-Achs | 25 m/min | ● | |||

| Z Achs | 10 mm/Min | ● | |||

| Tool Zäitschrëften | ISO30 12 Stéck | ||||

| Stroumspannung | 380V 50/60HZ | ● | |||

| Gewiicht | 2.3T | ||||

| Total Muecht | 18 kW | ● | |||

| Cutter Instrument | ● | ||||

Schreift Äre Message hei a schéckt en un eis